AI Needs Better Than Quartz

The Future of Clocks is in Small Silicon Machines

This post was made in collaboration with SiTime, who provided educational resources and compensated me for my time. All writing and opinions are my own.

For the past 15 years, I've focused a lot on the final result of the semiconductor process: the end products. Initially my career started with testing motherboards, before looking into processors, architecture, manufacturing, and the business side of these companies. With the explosion of machine learning and the buzzwords of AI, the hardware these companies produce have grown, with the biggest scale now going into multiple chiplets and thousands of watts. The latest NVIDIA NVL72 is a full server rack with 72 GPUs, 9 switches, and consumers 120 kilowatts. No-one really knows where the limit is, or how efficient we can build these things.

One of the fundamental aspects of all this hardware, since before I was even born (I'm an old millennial, for those keeping track), is one of frequency and clock signal. Whether we're talking the 0.985 megahertz of my old Commodore C64 or the multi-gigahertz of a modern computer chip, the ability to create and sustain a frequency that these tiny switches can use to turn electrons into cat photos has been a fundamental part of the industry.

So fundamental, that it is in fact a $10 billion industry. Absolutely everything needs some frequency generator to work, and in most cases it's not just one. The ability to also synchronize these frequencies to enable chips to talk to each other, or even parts of a chip to talk to other parts, is tricky. Large chips might need to use multiple frequencies, or distribute the same frequency across the whole design, so designs have to enable take that into account.

For the most of history, that clock was provided by a quartz crystal. Quartz has a stellar property in that it is piezoelectric - of a specified shape and size, if a force is applied, an alternating current with a regular frequency can be obtained using resonance. Billions of electronic devices globally have quartz crystals as clock generators - they come in self-contained packages to be used in everything from handheld devices to spacecraft. The integration of quartz into technology has been so thorough that even in my old overclocking days, if we wanted to increase the frequency of a CPU, we could replace the quartz crystal on the motherboard to get more frames in my games.

But therein lies the rub. Is quartz the best tool for the job? The recent push for machine learning hardware and a focus on sustainability and configurability has meant that businesses are looking to improve everything they can in a design - even the stuff that's been used for decades and is considered 'fundamental'.

This is where SiTime, the company I've been learning about, comes in. In their opinion, quartz no longer fits the bill for timing and clock generation.

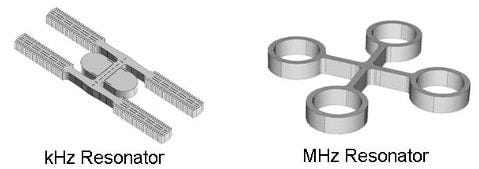

MEMS: Micro-Electrical-Mechanical

SiTime is a company that uses MEMS Technology - that's an acronym for micro-electro-mechanical. MEMS isn't new by any stretch, but it involves creating small mechanical devices (often in silicon) to do the job that we typically require big structures not in silicon to do. Some examples of MEMS that you're already familiar with include the sensors in your smartphone, detecting position, temperature, moisture.

With a specific design, the way a MEMS device moves in reaction to stimuli produces signals that can be interpreted. When you carry your phone in a pocket and walk, the tiny arms on a mechanical device will feel a force as you walk and help count the steps - or help the GPS signal predict where you are since the last GPS update without external reference.

I first came across MEMS as part of my Chemistry degree. At the time, the concept of microfluidics and lab-on-a-chip was a gateway into selective chemical reactions based on smaller dimensions. Lab-on-a-chip, or at least when I was taught, could potentially improve chemical yield of complex reactions through flowing microliters of reagents through a chip. Also, if your reagents happened to be expensive (complex pharmaceuticals, for example), then this was a way of controlling the early phase of manufacturing and development. Control of fluids was done electrically at the time, however small mechanical devices were being trialed to avoid the use of currents that could affect the reactions. They could also be used for monitoring and control.

MEMS is difficult to visualize in the sense that the devices are small - on the order of microns, rather than millimeters or meters. At that size, manufacturing them requires expertise - which in the case of silicon is lithography and micromachining, rather than simply a hammer and a chisel. We're used to a thermometer on a wall, not 50000 of them on the tip of your finger. As a result, one of the benefits of MEMs is in their size as well.

SiTime applies that MEMS concept to their three main markets: clock generators, resonators, and oscillators. The claim is that MEMS variants, compared to quartz, are a lot smaller, much more accurate, are lower power, suffer a much lower manufacturing variability, and because silicon, can be programmable.

To put this into perspective, I mentioned that clock generation is a $10b industry today. That's $4b in resonators, $5b in oscillators, and $1b in clocks (we'll get into the differences between these later). SiTime is addressing around $2.5-$3b of that addressable market today, with $144m in revenue.

SiTime: The Company

Originally spun out from Bosch, the company was formed on the premise that quartz timer production is a very mechanical process and too variable for what was needed in the market. Making quartz crystals with the right characteristics requires cutting, grinding into shape, polishing, and extensive testing. In the early 2000s, the advent of semiconductor manufacturing made the SiTime founders wonder if it was a suitable way to replace quartz.

MEMS resonators were actually invented in 1968, by IBM (of course it was IBM). The research into them was limited by the capabilities of the time, and they didn't take off because back then a mechanical physical process was just much simpler to scale than 'new' semiconductor lithography techniques. Quartz timing, as computing grew, became commoditized very quicky through the personal computing boom of the 80s. It was good enough, and often when things hit a minimum bar, there is no business incentive to go looking for alternatives.

At the turn of 2000, the consumer chip industry was starting to pick up pace. Kilohertz was turning into megahertz, and these new fangled things called GPUs were starting to do graphics. As we scale something like quartz up to higher frequencies, it still works, however the variability becomes more of an issue. We were entering an era where exact frequency to several decimal places matters. At 100 MHz for example, a 0.5% deviation means anything between 99.5 MHz and 100.5 MHz, making electronics unusable.

The original architects for SiTime had created technology outside of Bosch's traditional purview - Bosch was more focused on automotive segments. Exclusive licenses were negotiated, other investors came on board, and the five co-founders focused on siliconization. The premise was that other parts of the market were moving to silicon from other materials (eg LEDs to silicon, of HDD to SSDs), and this was an opportunity.

In 2007, the current CEO joined the company - Rajesh Vashist. The company was 100% focused on timing products, and from their own admittance, back then they were competitive on features and programmability of the silicon resonators, but didn't match the performance of quartz. It came to a head in 2012 when revenues flatlined at low tens of millions that the company shifted to all-new product lines aimed at surpassing current solutions in every aspect.

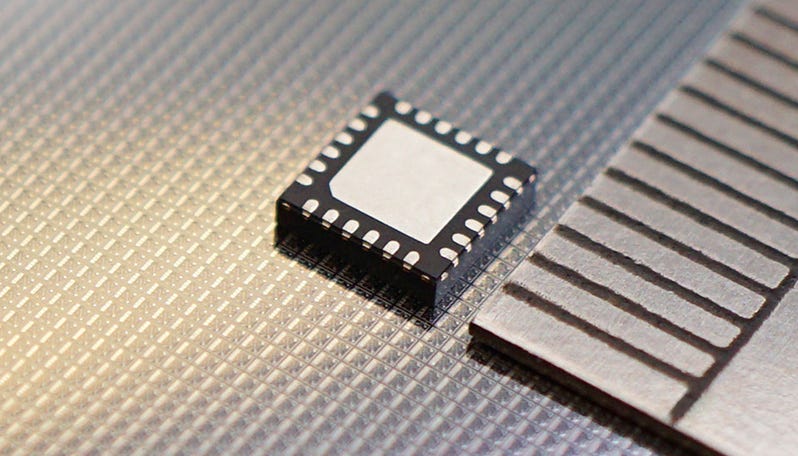

The first product of that refocus was a 32 kilohertz oscillator in 2013. It was 85% smaller than the competition, stable over a wide temperature range, durable, and succeeded in a market that was going bananas for smart wearables. Traction from smartwatch companies who wanted small, efficient, and accurate everything confirmed that the company was on the right track in targeting a market that other solutions aren't prepared for.

The next big wave for the technology was in the push for 5G. The increased demands for bandwidth, lower latency, higher density radio deployments for all weathers called for a lot of changes in how modern infrastructure was built and deployed. The range of 5G frequencies meant that in order to provide complete coverage, these access points would be closer together, and the telecom companies could no-longer be highly picky about deploying them where they wanted. This meant areas that had to be air cooled, and vibration resistant (truck going by), but also deal with thermal gradients and electrical noise.

This requirement spurned product lines known as environmentally resilient - oscillators that could withstand vibration, shock, airflow, thermals, and noise. Quartz isn't good at many of those in a given instant - for example, a 32 kilohertz oscillator is often provided with an accuracy to 300 parts per million when stable. When in unstable conditions, these issues can amplify. (Parts per million, or ppm, is a common metric in oscillators - 300 ppm is 0.03%.) An equivalent MEMS oscillator, by comparison, offers around 25 ppm of stability over a wider range of environmental factors. It was still smaller and lower power than other parts.

It was around this time, in 2014, that SiTime was acquired by the Japanese company Megachips. Even though it was acquired, the two operated independently due to limited overlap in the businesses and business models. In 2014 revenue was $19m, and by 2019 that had risen to $83m. In 2019 SiTime listed on NASDAQ - Megachips still remains the biggest shareholder.

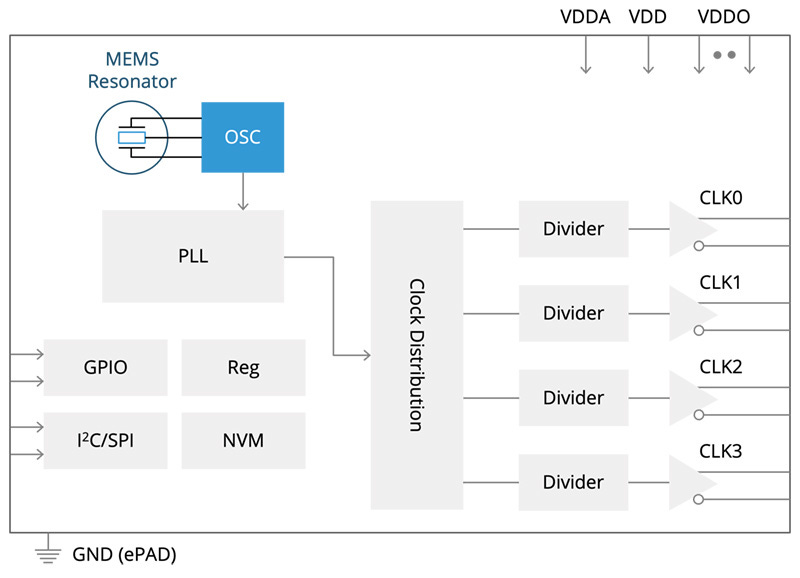

In that time, 95% of SiTime's revenue has come from oscillators - these are actively powered single output clock devices. To expand into the clock generator business (i.e., a device with multiple clock outputs and programmability), the company partnered with Aura Semiconductor. In 2020 they created a clock-SoC, or clock-system-on-chip, and a new market with the Cascade product line. This aimed at simplifying the design cycle and time to market by packaging multiple onboard elements into one. In 2023, SiTime acquired all of Aura's products, and brought to worldwide customers.

The latest product line is called Chorus. This is a fully home-grown MEMS clock generator for the datacenter, and as a generator, contains resonators and multiple clocks on an chip, reducing the need for multiple clock sources and installing multiple components. The point is that every modern device has multiple clocks - these either require a master signal which is then divided/multiplied given a ratio, or simply separate input signals as required.

Customers in this space are looking to remove quartz for multiple reasons.

Simplicity: why use more components when few component do well

Reliability: The reliability of quartz in these designs is often 50-60 million hours between failures. MEMS is often 1 billion or more.

Power: Constant switching requires power, and time to turn on/off matters, especially for mobile devices that use radio interfaces, such as smart meters or smartphones. Quartz stability over temperature could be 200-300 ppm, whereas MEMs can be 3 ppm, a 100x improvement. This means the time needed for the RF to be enabled due to that stability window is shorter, leading to up to 30% power savings.

Power #2: Sometimes quartz will have built-in thermal stable environments, eg a ‘mini-oven’, to ensure stability. Removing that oven saves power - or using a similar concept for MEMS gives even better stability still at lower power. Heating up something that's microns in size is easier than keeping a big crystal thermally stable.

Accuracy: With everything being connected, keeping accurate time across a datacenter or between datacenter regions is itself a challenge. The order of operations matters, and the most accurate MEMS oscillators offer 0.001 ppm (aka 1 ppb) accuracy for only 420 mW. To do this with quartz requires three times the power. (I did look at an atomic clock on a PCIe card in 2021, designed by Meta, capable of 0.001 ppb accuracy, but that was many watts of power. It goes to show that how some of these requirements scale.)

As a result, SiTime is seeing traction with these sorts of products in devices like SmartNICs and networking switches. In these devices, multiple MEMS clocks combined with configurability streamline the design and ultimately time to market.

The Problem with MEMS: Education

The growth in the market sounds dependent on the engineers. Everyone has used quartz alternatives for decades, so why stop now? I mean, no-one ever went broke buying quartz, right? Out of my discussions with VPs at the company, their biggest issue is market education. Quartz is very much a vertically integrated, commodity turnkey solution, and a lot of designers are very used to it. MEMS by contrast introduces, alongside better power/reliability/simplicity/accuracy, features and customizability that veteran engineers aren't used to.

The expectation is that with the new wave of compute in both the cloud and at the edge, and the higher requirements to enable it all, that the benefits of MEMS justify their use. SiTime is working with clients looking at further product integration, modularization, packaging, and a ‘resonator plus IP’ roadmap.

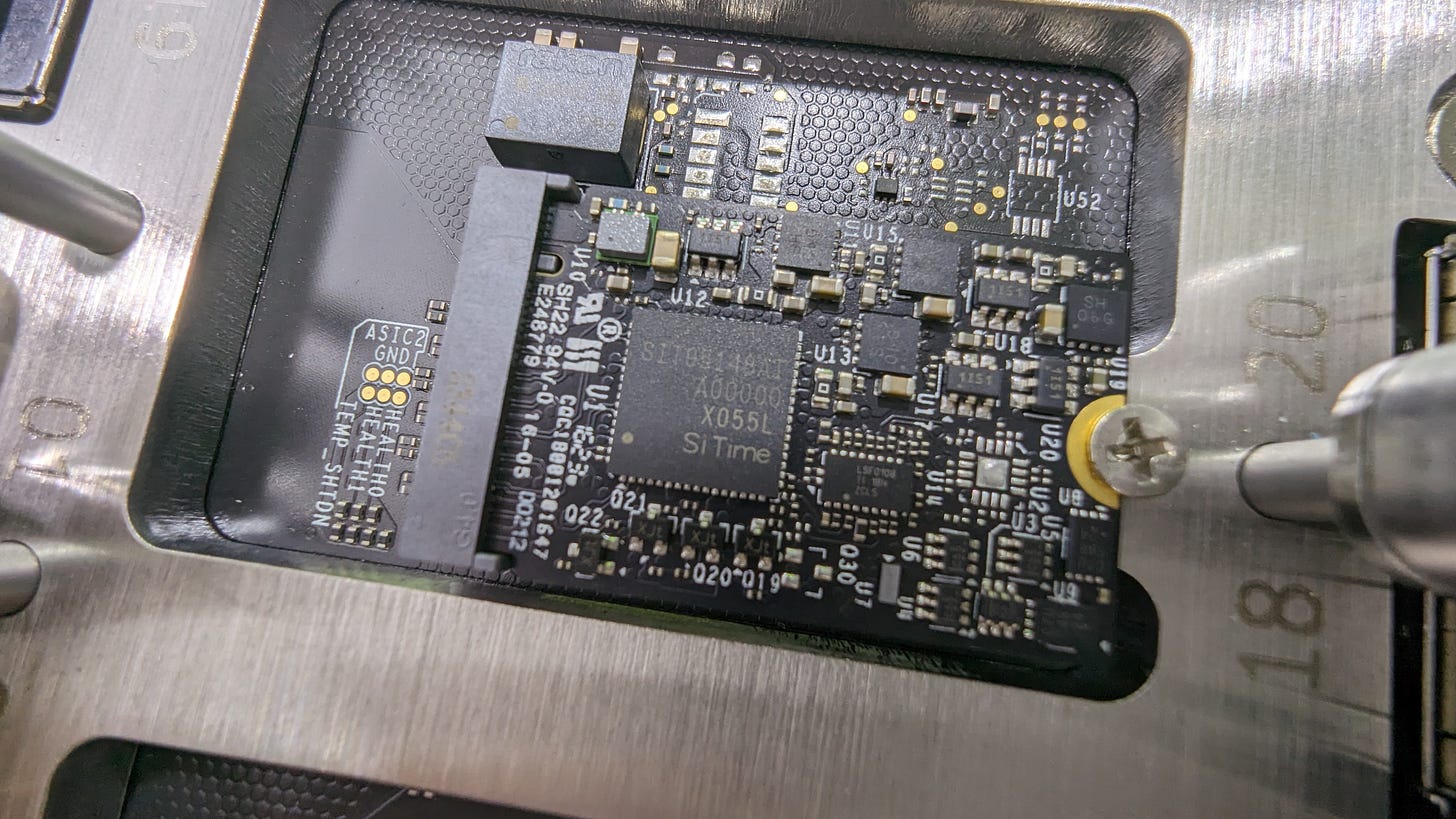

To that end, I had the fortuitous luck to see one of SiTime's chips at Computex 2024. While the company wasn’t at the show, I was at NVIDIA's enterprise demonstration area, and was looking intently at the new Blackwell GPUs as well as some of the updates to the networking family. It's in the networking family I found a SiTime MEMS solution - inside the Spectrum-X ethernet switch. This switch is a beast, occupying at least a 4U in a rack and having (I believe) 96 ports of 800 GbE. Inside, underneath each of the internal Spectrum switch chips, was a SiTime device providing the clock.

SiTime's Market

As mentioned, the timing market is around $10 billion today, split 4/5/1 with resonators, oscillators, and clocks.

Resonator

Oscillator

Clock

Most of the resonator market is $0.10 machined crystal. Literal cutters, polishers, and post-manufacturing testing to get within a few hundred ppm. Today SiTime addresses $2.5-$3.0 billion of the overall market, and 95% of their revenue comes from oscillators. Later this year, the company will launch a standalone passive resonator, increasing that addressable market to $3.5 billion.

This diversification strategy aims to enhance their presence in the resonator segment and leverage the advantages of MEMS technology to penetrate deeper into the clock generation market. SiTime’s focus on programmability and integration aligns with the evolving demands of industries reliant on precise timing solutions, including telecommunications, data centers, and consumer electronics.

Future Trends and Innovations in Timing Technology

The future of timing technology, as illustrated by companies like SiTime, is anticipated to involve significant advancements and broader adoption across various industries. A key trend driving this evolution is the increasing demand for higher precision and reliability in timing solutions, especially in sectors such as telecommunications, data centers, and consumer electronics. As networks evolve towards 5G and beyond, the need for accurate, stable, and power-efficient timing devices becomes crucial. MEMS-based resonators and oscillators, with their performance characteristics compared to traditional quartz, appear well-suited to meet these demands, and a number of markets could be poised to adopt this technology:

The Internet of Things (IoT) and edge computing are expanding fields that require robust, miniaturized, and low-power timing solutions. MEMS oscillators and resonators, due to their small size and low energy consumption, are suitable for these applications. Devices at the edge of networks, such as smart sensors and actuators, need precise timing to ensure synchronized operations and efficient data processing. Programmable MEMS devices can be tailored to specific application needs, offering flexibility for IoT deployments.

As 5G and 6G networks are deployed, the demand for timing devices that can withstand environmental stresses while maintaining high accuracy is growing. MEMS-based oscillators are advancing to meet these needs with enhanced performance in terms of vibration resistance, thermal stability, and electrical noise immunity. These features are important for maintaining reliable communication links in dense urban environments and harsh industrial settings. Future innovations may include more compact and integrated timing modules, further reducing the footprint and power requirements of network infrastructure components.

Artificial intelligence (AI) and machine learning (ML) systems require precise timing for data synchronization and efficient processing. MEMS-based timing solutions can support the development of more sophisticated AI hardware by providing accurate clock signals that enhance the performance of processors and accelerators. Enabling a more accurate clock signal will also assist in optimizing power consumption, a key element in the future of large-scale compute.

Other future innovations in timing technology will undoubtedly focus on the performance needed for next generation requirements, but may also include the development of multi-functional devices that combine timing with adjacent functionality, further reducing component count and power consumption. Advances in materials science and nanofabrication techniques are likely to lead to smaller, more efficient, and more robust MEMS devices. Additionally, the integration of MEMS timing solutions with emerging technologies such as quantum computing and advanced wireless communications could open new frontiers for precision timing applications.

Conclusion: Evolution

The timing market is evolving with MEMS technology, offering an alternative to traditional quartz-based solutions. As industries demand more efficient, accurate, and reliable timing mechanisms, SiTime is a market leader in this, offering MEMS-based clocks, oscillators, and resonators that showcase a market in demand for smaller, more power-efficient, and highly stable options. The fact that I was able to see it inside NVIDIA’s networking switch on a random showcase highlights the need for such designs.

The shift towards MEMS technology presents challenges in market education and adoption, it offers potential improvements in efficiency and precision for electronic devices. As companies like SiTime continue to develop and introduce MEMS solutions, they may become increasingly integral in various industries, displacing quartz - which at this point seems no longer fit for purpose for the new wave of compute in the pipeline.

What's the manifold of stability vs. power vs. price for MEMS vs. TCXO based real-time clock units? Oscillators?

Somewhere in my collection of cool electronics surplus I bought for teaching electronics, there is a tiny oscillator that I think was for a '70s Seiko wristwatch. If I recall correctly, it's about 7 x 5 mm, with gold-plated ends and a window revealing a tiny tuning fork.

HEY! I like to see this - cool spot on the computex floor. SiTime is def probably happy about this.